Hybrid Cooling Towers

Hybrid Cooling Towers

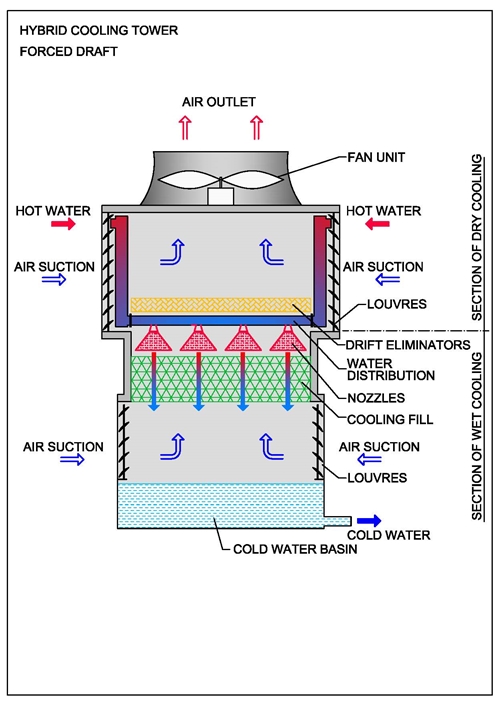

The hybrid cooling towers represent a suitable combination of wet and dry cooling with a favourable impact on the environment, meeting demanding environmental requirements.

They allow for the reduction of steam drift (the “steam plume”, especially visible during cold wet weather and in winter, when it can lead to icing). The elimination of the steam plume is particularly beneficial in urban areas, industrial areas, and close to roads with the potential of icing. The hybrid cooling towers reduce the consumption of water and provide total heat rate as required by the customer.

Components:

- outher shell (material: FRP, steel, stainless steel, concrete)

- supporting structure

- water basin

- fan stack

- cooling fill

- drift eliminators

- dry cooling exchangers

- mixing modules

- fan with drive

- water distribution system including sprying nozzles

The hybrid cooling tower works with the principle of wet cooling, whereas it is supplemented with the dry cooling module. The purpose of this module is to reduce the cooling water temperature, using the surrounding air before the water enters the wet section. Hot air from dry cooling is mixed with saturated air from the wet section, thus eliminating the steam plume.

Industrial applicatio:

- energy industries

- petrochemical industry

- chemical industry

- engineering industry and metallurgy

- plastic and rubber industry

- paper industry

- manufacturing industry (food-processing, sugar refineries)

Potential optimization:

- used materials and components

- total cooling efficiency

- operation and maintenance economy

- noise elimination

- reduction of environmental impact (water and energy savings)

- ATEX design for explosion hazard spaces